Grossly False Narrative of $100 “Click PLC”

AutomationDirect wants you to believe that you can get a Click PLC for $100. It is a classic “bait-and-hook”.

Here is the truth: For a simple 16 DI, 8DO 4RLO system

So far we are at $341

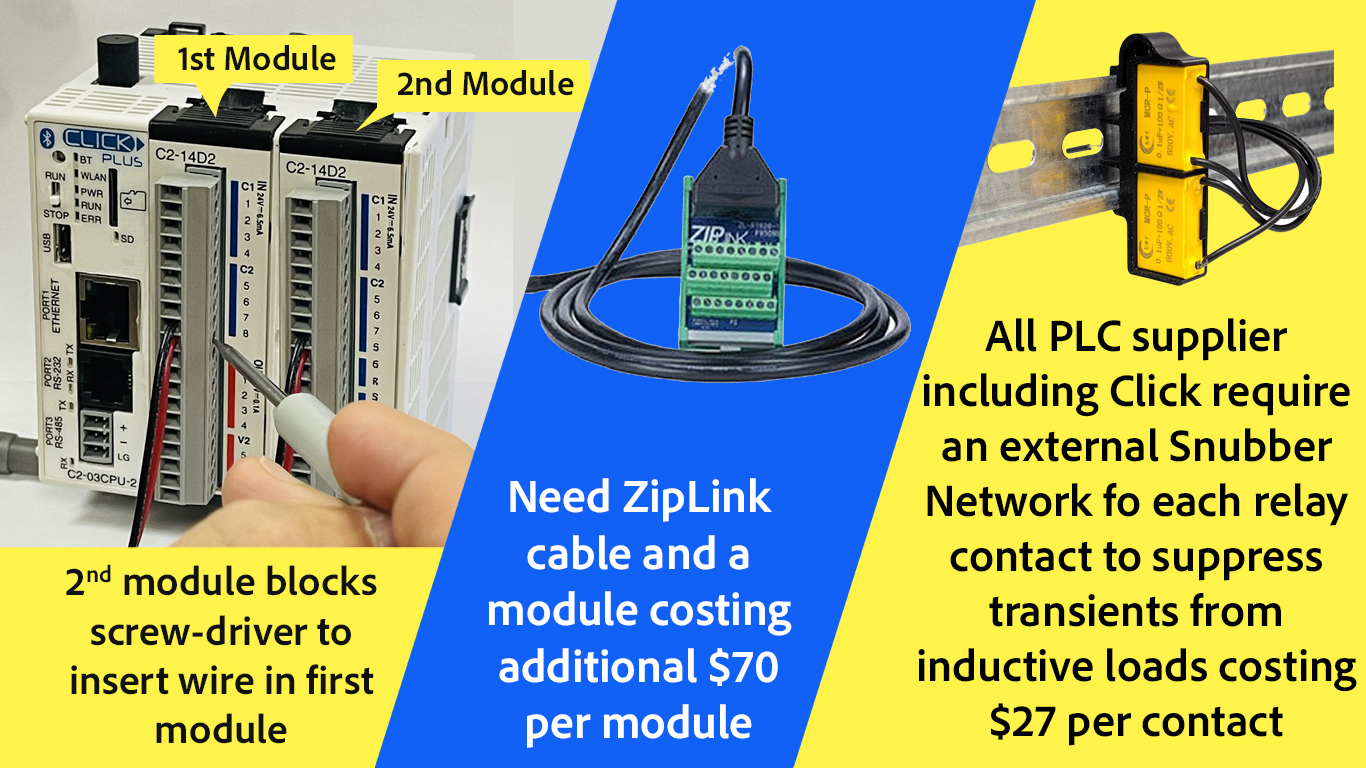

We need ZIP links to be able to connect wires to IO terminals. Each ZIP link along with the cable costs about $70, 4 ZIP links in this system will add: $279

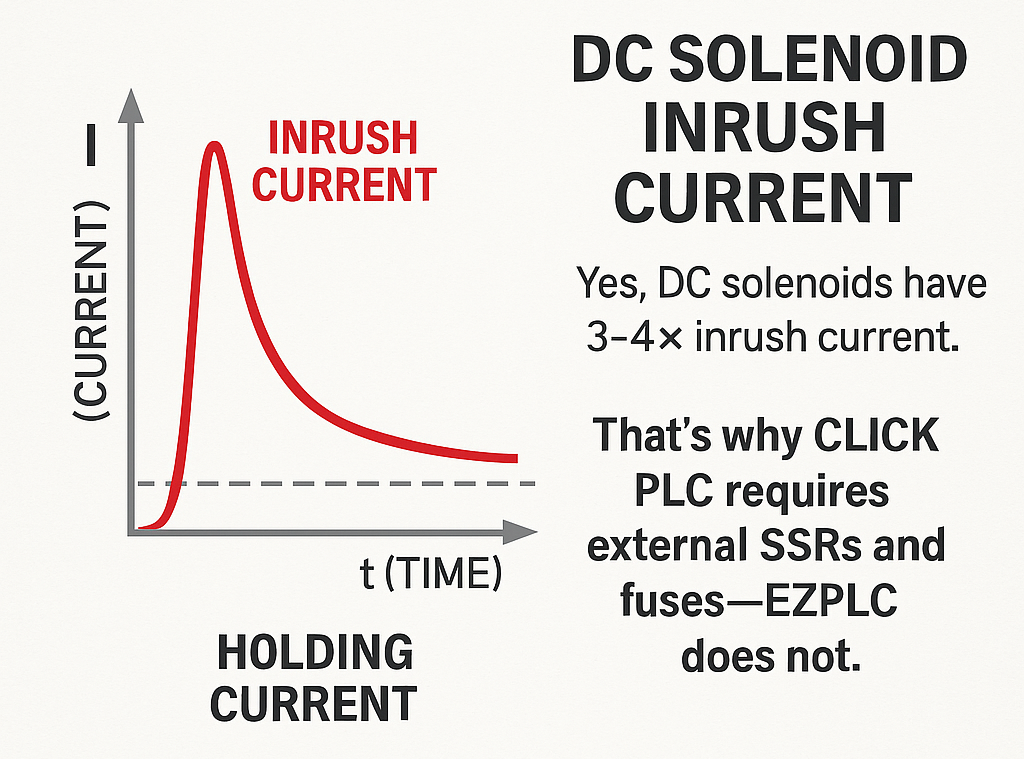

DC solenoids have an inrush current 3-4 times its steady state current, requiring external relays and fuses

Total: ClickPLC $898, and not $100. In-rush current in DC solenoids explained DC solenoids are an inductive load that present a momentary short to it's driver circuit. For example even a small 6W 24V DC that has a steady state current of 250 mA will have an in-rush current of 750mA to 1A. This in-rush current could last only a few µs but the output transistor or Mosfet driving it needs to have a capability of handling 1A. Therefore a prudent automation engineer will put in an external solid state relay to drive this DC solenoid. A typical solid state relay (such as Crydom) will cost $57 for each SSR and there would be at least a lobor cost of $5 to mount and connect each solid state relay. Now solid state relays are not short circuit proof leaving the Automation engineer no choice but to put a fast acting fuse in series with the coil of the DC solenoid costing additional material and labor. Each PLC output driving a DC solenoid will cost at least additional $75 per output. On first glance it would appear that the problem is solved even though it costs substantial additional money, but these fuses present a maintenance problem in that the engineer/technician troubleshooting it has to find this fuse and replace it in case the solenoid shorted.

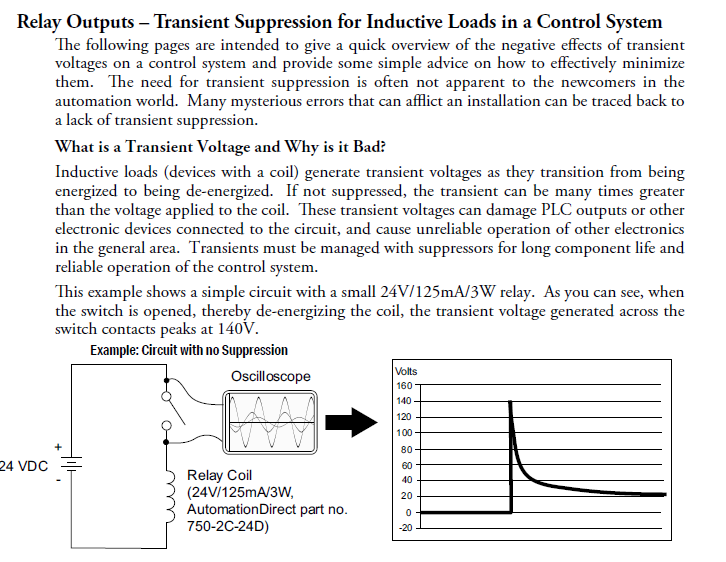

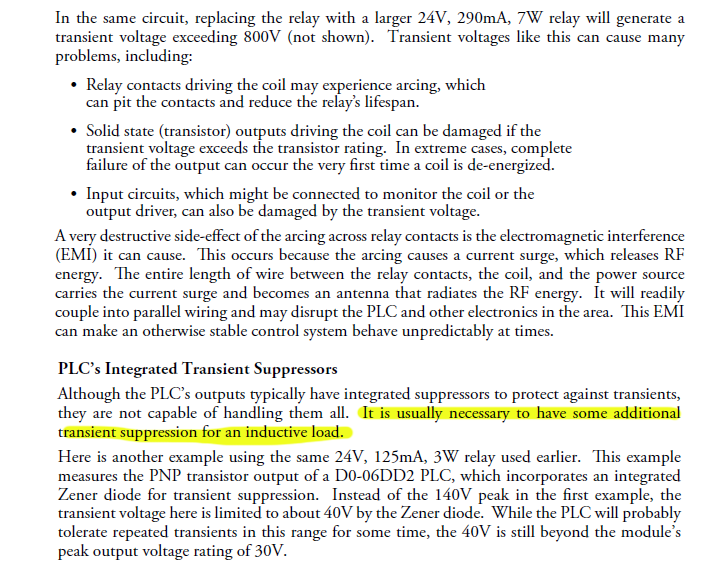

* Note 1 explanation ADC requires transient supression for inductive loads driven by relay contacts

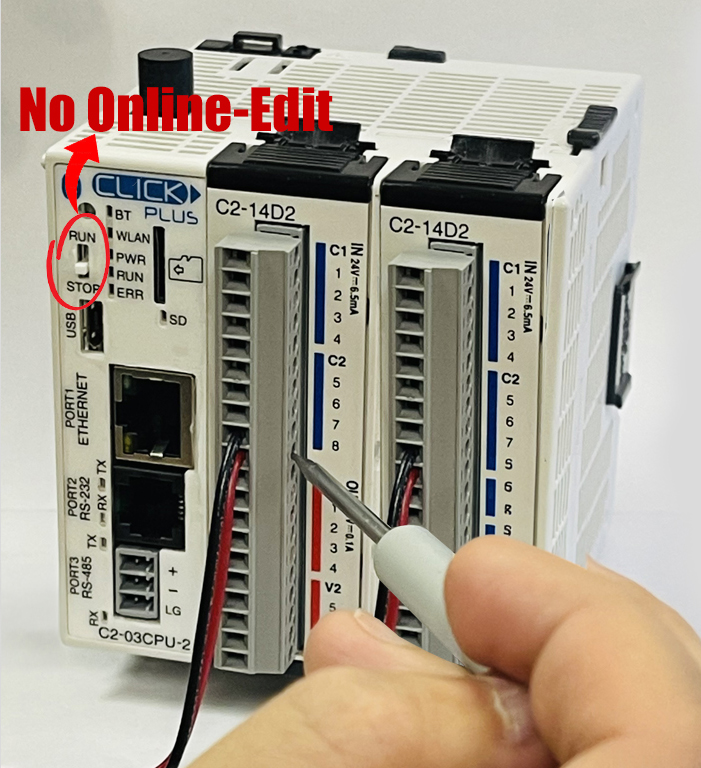

Check Click's Fragility before you buy or specify - holding clip and module stability. To your left is a CLICK IO module. See it's mechanical fragility holding clip as well as the entire body. Nothing is screwed down, it's mostly fragile snap-in. We strongly recommend that you you procure a basic CLICK CPU and 2 IO modules and check out for yourselves. EZPLC IO modules are screwed in securely to the base of the PLC. Check Click's Fragility before you buy or specify - LED indicator lights for IO. To your right you'll see how CLICK shows LED indicators for each input or output by having fragile light carrying tube that can totally confuse a maintenance person on which input or output is activated. EZPLC IO module indicator lights are solid on the circuit board.

CLICK, vintage 1980's, has no PLC Online-edit. Click PLC is really not a PLC. It is more like a basic smart relay. Starting 1990's all credible PLCs introduced in the market had PLC Online-Edit so that program developer during machine deisgn or during machine startup can edit the ladder logic conveniently without having to switch from run mote to program mode and them back to run mode. Whereas Click PLC allow entry of data into PLC registers, it does not allow change in ladder logic. Thus Click, if it is to be considered a PLC, it is a very basic PLC. EZPLC has full PLC Online-Edit capability.

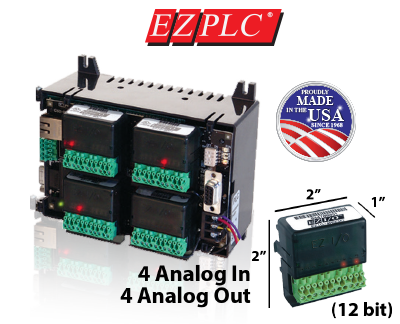

EZPLC is 2 for 1 against properly configured Click or Click Plus, and would be 3 for 1 with 47% tariffs on Made in China.

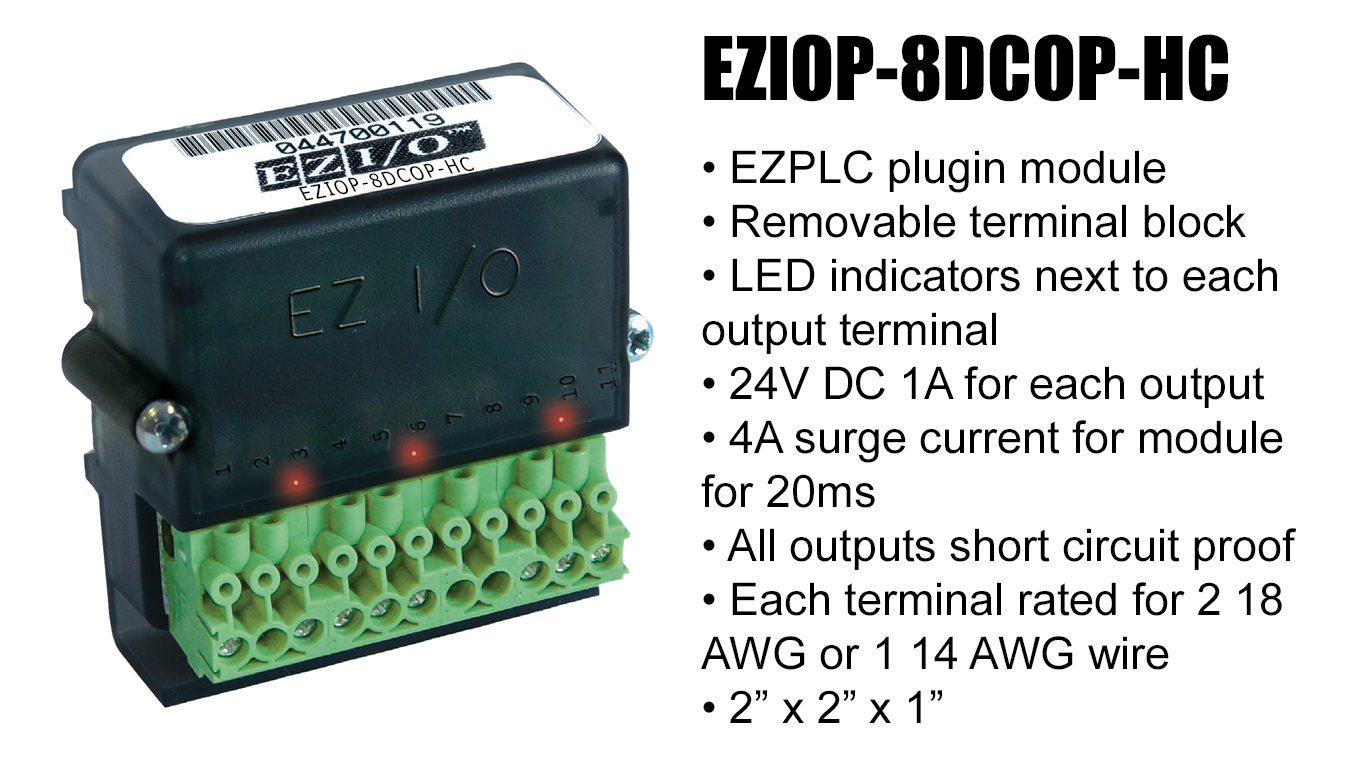

Unique Patent Pending High Current (HC) DC Output modules for DC solenoids and Fans with Surge Current saving a lot of cost. These High Current (HC) modules are specified to carry 1 Amp Steady State current to drive 24W solenoid and 4 Amp Surge current for 20 milliseconds. These DC inductive loads have 3-4 times in-rush current needing external solid-state relay, that costs $, Panel space and labor and yet no Short Circuit Protection. For short circuit protection, AutomationDirect recommends adding fast acting fuses for each output. No such need with HC Modules.

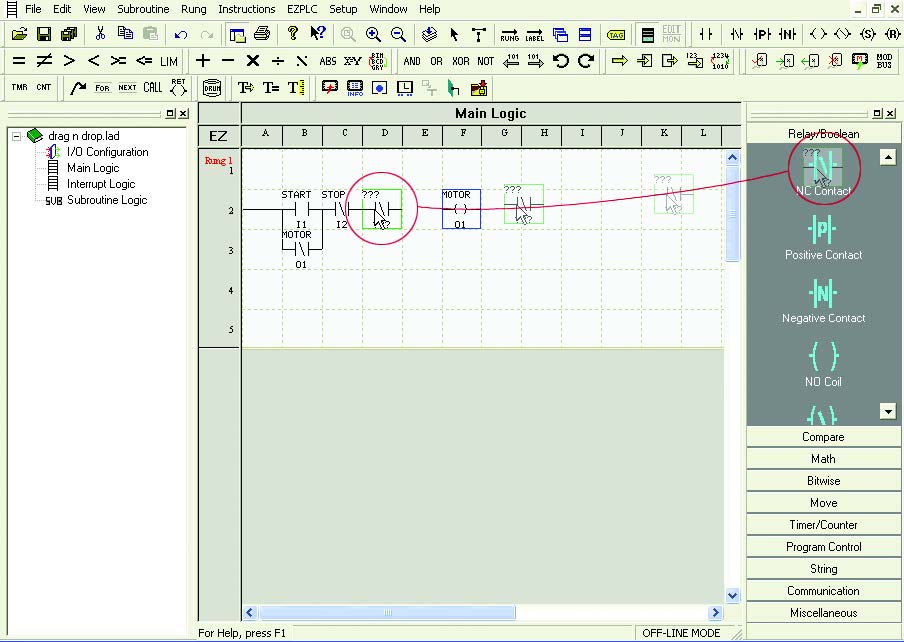

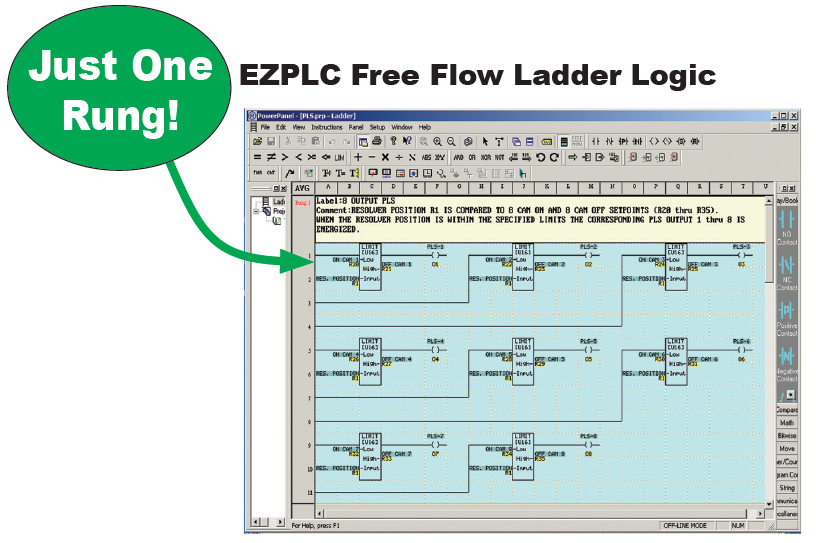

Free Flow Drag-n-Drop Programming Software 1 time Buy for $137 Today, one single plant is likely to have multiple brands of PLCs, requiring Electricians & Maintenance personnel to remember these multiple languages. One may have learnt AutomationDirect PLC Programming Language (different for all different PLCs like Click, BRX, Do-More etc.) or Rockwell, RSLogix months ago, but had not gotten a chance to use it. Troubleshooting the PLC system months later, it is going to be difficult trying to remember the correct syntax. If it is a Siemens PLC, it might take the same person a week to just get started. It is in this context the EZPLC Drag-n-Drop software was developed. It is essentially a graphical language. You draw the ladder intuitively. No complicated syntax and rules. It can be learned in a few minutes. Tens of thousands of users learned this software without having to ever attend a class. Unique Patent Pending Free Flow Logic The concept of this Free Flow Ladder Logic is to create less restricted rungs of logic. This saves the user rung space and valuable scan time. On the right you will see an example of Free Flow Ladder-Logic. As you can see the Free Flow logic allows logic to be placed and connected anywhere in the rung rather than creating a new rung. This allows the user to spend more time on other parts of the machine development and let the CPU do more of the work of solving the logic.

|

1-877-774-3279

B.A.B.A. Compliant

B.A.B.A. Compliant

New Application Support

(7 days/wk)

cell 563-340-1464