IIoT and PLC (Programmable Logic Controller)

by Vaidyanath "Doc" Nanjundaiah

The world is emerging. Gone are the days where we used to sit in front of the TV for 6’o clock news to know what’s happening around us! Now you have the access to information on your fingertips! Tablets, smart phones rule the world. Technology has evolved and the world is becoming smaller every day! Same applies to industrial automation. It has evolved. Relays were replaced by PLC’s. Serial communications between devices changed to Ethernet. PLC’s have evolved throughout the history of Industrial Automation. Now it’s IIoT. This is something new to the industrial automation industry and it is definitely going to change the way things work. It’s just a matter of time. The only question here is, will you adapt or go obsolete?

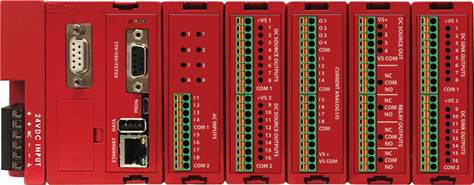

EZ Automation proudly introduces EZRack PLC!

EZ Automation proudly introduces EZRack PLC!

The very first American Manufactured PLC with IIoT capability which is taking the world by storm!

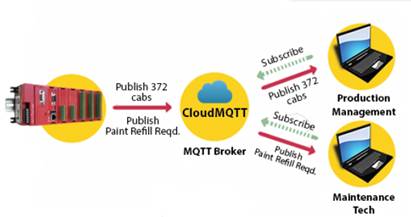

With built in MQTT (Message Queuing Telemetry Transport) protocol support, it can talk to Edge Gateway devices such as temperature, pressure, flow sensors and actuators, and transfer the data to a cloud. This data can be further segregated and sent to different departments of a company for analysis and decision making in real time!

EZRack is not only a powerful PLC but also a low cost Edge Gateway device.

EZRack PLC’s built in IIoT and MQTT protocol acts as a bridge between the existing operational technology within a plant and plant database networks, so valuable data can be shared reliably and securely to improve plant productivity and efficiency.

EZRack PLC’s built in IIoT and MQTT protocol acts as a bridge between the existing operational technology within a plant and plant database networks, so valuable data can be shared reliably and securely to improve plant productivity and efficiency.

It helps in predictive maintenance, it’s an innovative way to track and analyze equipment and it increases revenue.

It also has a USB port to log historic data in csv format, which can be used for analysis and to perform corrective action. It can send user specific data to the cloud which can be accessed using smart devices like a phone, tablet or a laptop.

Being in technical support, I have heard this phrase many times, “If it ain’t broke, don’t fix it”.

Being in technical support, I have heard this phrase many times, “If it ain’t broke, don’t fix it”.

But in this technologically advanced era, why wait until it’s broke? Why can’t we use the available technology, which is inexpensive and very simple to implement, and do a preventative or predictive maintenance? The sensors, actuators or switches which can send data to EZRack PLC and EZRack can analyze it and send that information to the head of maintenance department in real time! No machine shutdown, no downtime, no revenue loss.

Time is money!

Time is money!

Preventive or predictive maintenance in a nut shell increases productivity by 25%, reduces costs by 30% and reduces downtime by 45%.

EZRack PLC helps not to react to breakdowns but take the proactive approach by sending the real time data to the plant manager or head of maintenance and thereby saving thousands of dollars!

But wait, there is more! Why use EZRack PLC only for maintaining machinery? Why can’t we use it for plant productivity and efficiency?

EZRack PLC can send real time production data and plant efficiency. It can analyze where the bottlenecks occur, which machines jam etc. and send that information to the production manager in real time. Accurate and comprehensive real time information about plant floor operations will help to make informed decisions to achieve better productivity and plant efficiency!

Benefits of IIoT in EZRack PLC:

Benefits of IIoT in EZRack PLC:

- Easy and inexpensive to implement.

- Real time data always on your fingertips.

- Increases plant productivity and efficiency.

- Decreases downtime from predictive maintenance.

- Improves operational efficiency.

- Boosts revenue.

Overall benefits of IIoT built in to a PLC has lots of advantages. All leading companies already have plans in place to adapt to this revolution in industrial automation. IIoT is the future and EZAutomation’s EZRack PLC is in the forefront. Implementation costs are low and payoffs come quickly.

The question is, “Will you adapt or will you go obsolete?”