EZ iMarquee - Productivity Monitoring and its Importance in Manufacturing Plants

Most manufacturing plants whether it’s small, medium or large have implemented processes like Six Sigma, Lean Manufacturing and Kaizen to improve their manufacturing process and drive productivity to stay ahead of the competition and maintain the competitive edge. To achieve this, there should be no barriers between departments or personnel. Rather the entire organization should work together to share and solve problems.

Most manufacturing plants whether it’s small, medium or large have implemented processes like Six Sigma, Lean Manufacturing and Kaizen to improve their manufacturing process and drive productivity to stay ahead of the competition and maintain the competitive edge. To achieve this, there should be no barriers between departments or personnel. Rather the entire organization should work together to share and solve problems.

Manufacturing plants should use tools to access, analyze and track manufacturing process. Visual management is one of those tools. Displaying critical information like production count, actual target, production efficiency and safety messages to the entire plant will help the plant personnel to have a better understanding of what is going on, where they currently stand and how to improve efficiency. This information also allows supervisors or the plant managers to analyze bottle necks or issues in real time, monitor performance and fix issues which can help to achieve the intended or set target.

All machines now a days are automated and they use a smart controller like a PLC. These PLCs control a particular machine or the whole process in the plant. They also process data like production count, alarms, efficiency etc. Different machine manufacturers (OEMs) use different make and model PLCs and they have their own communication protocols.

EZAutomation introduces the EZ iMarquee which monitors and displays plant productivity without having to change anything in the existing PLC ladder logic. It can connect to all major brands of PLCs on their respective communication protocols like EtherNet/IP, Modbus TCP/IP, Siemens ISO TCP/IP, GE SRTP, EZ TCP/IP, Do-more Ethernet and other serial drivers to display important data and alarms to the entire plant floor in real time.

Important Features:

- Monitors and displays plant productivity with absolutely no PLC ladder logic change.

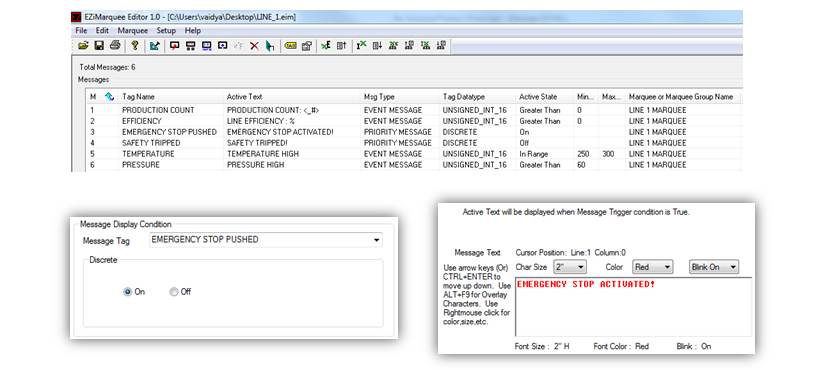

- Free EZ iMarquee Programming Software.

Displays Alarms as a priority message; superseding the normal messages.

- Supports all major PLC communication protocols.

- Built-in Serial and Ethernet ports.

- Built-in Math Logic / Scripting for advanced programming.

- Import tag database from PLC and add messages to be displayed on EZ iMarquee depending on event condition of a Boolean/Discrete tag or a value of an Integer tag.

Return on Investment:

ROI metrics in a manufacturing environment depends on several factors like productivity, quality, safety, training, maintenance methods etc. Any metrics, if not measured is not useful. Not only that, if that data does not reach the right person(s) who is responsible for taking corrective action, and at the right time, that data is useless.

A typical manufacturing plant will have several production lines, these lines will have machines manufactured by different OEMs, who would have used different control systems or PLCs.

EZ iMarquee can communicate with almost all brands of PLCs without having to make any ladder logic or programming change and will display data to the entire plant. Data which is useful and helps plants to achieve the desired results. There is absolutely no need to use different brands of visual display devices to talk to different PLCs in the plant. Built in advanced math and scripting feature in the software can be used to calculate machine efficiency and line efficiency and display it for the whole plant floor. EZ iMarquee is ALL in ONE!

Programming is so EZ, just import the PLC tag database, assign the condition, write a message to be displayed on marquee and download. EZ as 1-2-3!

• EZ iMarquee can be used for efficient plant wide communication.

• Production schedule, efficiency, goals etc. can be broadcasted plant wide.

• Bottle necks, Alarms, Machine maintenance can be effectively displayed.

• An excellent ROI for a fraction of cost.

Conclusion:

Accurate and comprehensive real time information about plant floor operations empowers plant managers / supervisors to make informed decisions that help drive productivity. EZ iMarquee empowers them to achieve this.