Turning Raw Data into Actionable Information

by Vaidyanath "Doc" Nanjundaiah

Data is very important in process industries. Data is everywhere and it is awesome. But it can sometimes easily lead to data overload, not being looked at, or being ignored. Different people can interpret the same data differently. The key to turning data into actionable insight comes from establishing context and knowing the business goals. You cannot take action on data if you don’t know what it means or why is it significant.

With the technological advancements and increase in plant floor automation and connectivity to enterprise networks, todays process industries have a plethora of sensors, switches and transmitters which have data and can provide us with some useful information.

With the technological advancements and increase in plant floor automation and connectivity to enterprise networks, todays process industries have a plethora of sensors, switches and transmitters which have data and can provide us with some useful information.

Manufacturing plants also generate large amounts of data that can be collected and stored for data analysis and profiling. Data collection is simple, but if one does not know what to collect, how to analyze, and act on it, then that data is not useful.

Another important aspect of data is that not everybody needs everything. Different departments need different data for analysis.

For instance, maintenance departments need data from sensors and switches which they can analyze to determine machine health and safety. They can use it for preventative maintenance or scheduled maintenance. Plant managers need data which helps to analyze productivity, target, and goals. Plant supervisors need data to help plan production. Quality Control needs data to verify and control the quality of the manufactured product. So data must be segregated to help different departments to achieve the company’s common goal.

There are two types of data. Historical data and Real time data. Historical data provides a clear view of the past that can offer solid insights into where improvements need to be made. It captures process variables over a period of time which can be used for various calculations and estimations. Storing this information for future analytical needs helps management to not repeat the same mistakes again. But historical data is huge. If it is not used or not properly analyzed, it is useless. Real time data is time critical and one has to act upon it almost immediately. In process industries, by monitoring equipment behavior and identifying malfunctions, companies can maximize their operating uptime and output. Companies can use real time data to satisfy their customers demand for a particular product by changing their production schedules on the fly.

There are two types of data. Historical data and Real time data. Historical data provides a clear view of the past that can offer solid insights into where improvements need to be made. It captures process variables over a period of time which can be used for various calculations and estimations. Storing this information for future analytical needs helps management to not repeat the same mistakes again. But historical data is huge. If it is not used or not properly analyzed, it is useless. Real time data is time critical and one has to act upon it almost immediately. In process industries, by monitoring equipment behavior and identifying malfunctions, companies can maximize their operating uptime and output. Companies can use real time data to satisfy their customers demand for a particular product by changing their production schedules on the fly.

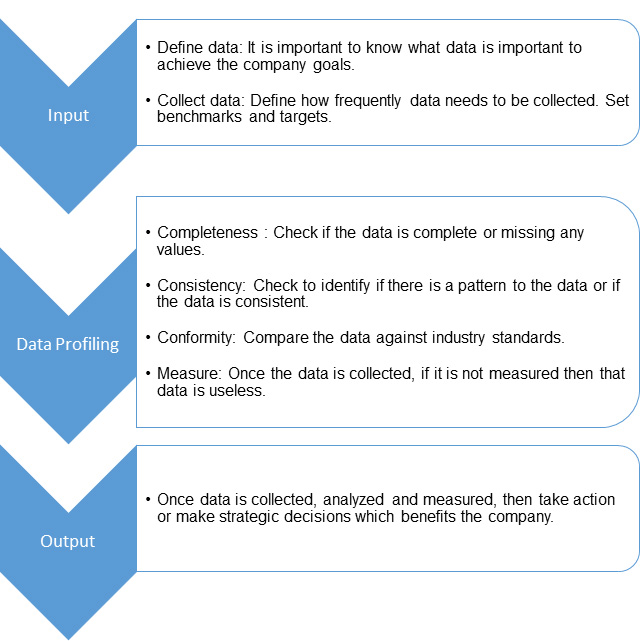

Raw data can be easily turned into actionable information by following some simple basic steps:

Industrial Internet of Things (IIoT), Industrie 4.0 is making news for a good reason. If properly executed, it can decrease downtime, enhance productivity, reduce operating costs, and support predictive maintenance. The level of insight and intelligence the technology delivers brings a significant competitive advantage to early adopters. The question is how to go from concept to reality. The challenging part is converting it to actionable insights. Process Automation Controllers like EZRack, focus on the interconnectivity and utilization of powerful data in a manufacturing environment. It acts as a bridge between the existing operational technology within a plant and the enterprise network, so valuable data can be shared reliably and securely to improve plant productivity and efficiency. The driving philosophy behind IIoT is that smart machines are better than humans at accurately and consistently capturing and communicating data.

Industrial Internet of Things (IIoT), Industrie 4.0 is making news for a good reason. If properly executed, it can decrease downtime, enhance productivity, reduce operating costs, and support predictive maintenance. The level of insight and intelligence the technology delivers brings a significant competitive advantage to early adopters. The question is how to go from concept to reality. The challenging part is converting it to actionable insights. Process Automation Controllers like EZRack, focus on the interconnectivity and utilization of powerful data in a manufacturing environment. It acts as a bridge between the existing operational technology within a plant and the enterprise network, so valuable data can be shared reliably and securely to improve plant productivity and efficiency. The driving philosophy behind IIoT is that smart machines are better than humans at accurately and consistently capturing and communicating data.

Conclusion: For companies to succeed in achieving their goals, getting the big data to a granular level is the key. With advancements in technology, companies can derive the information they need to provide more accurate forecasting, make better strategic decisions, and generate more profits.