Real Time Data Collection - Real Time vs. Historical Data

by Paul Figie, Application Engineer, EZAutomation

We all have heard you can never have too much information. We have also heard of Information overload!

Using Data Collection in real time processes determining what data to collect and how often can be challenging at the least. To make useful Collection schemes that work and get used has to be a collective effort. (Excuse the pun).

We all have put together many Data collection schemes only to generate files that never get looked at. Not because the information wasn’t useful but those who had access to that information did not apply the data in a way that helped the process that they were in charge of. I have had other cases that the Data collected is used daily and has effectively made production and processes more efficient. That being said I will try to address an approach to Data collection that can be used and is successful.

Perception & Presentation

Any Data that is not understood or misinterpreted is pretty much useless. As Engineers we have good understanding of the data we collect and how it applies to the process. But we have to go a step further and explain what the data means and how to apply it to those who are going to actually use it. Presenting the data in a clear and useful format is a must. I will go even further to say that if the intended end user of your collected data doesn’t think it is useful, it won’t get used.

Real Time data vs Historical data

Real Time data vs Historical data

In today’s technologically changing world, everything is on your fingertips. Decisions are made on the fly. We no longer have to wait for historical data analysis to make a decision. Data and trends can be accessed through smart phones, tablets. But historical data tells us the past trends. It helps us to analyze mistakes and corrective action which needs to take place to make the process more effective. But it takes time and effort to analyze and make a decision.

The combination of real time and historic data can help us to predict and take corrective action, which will help companies to be more productive and emerge globally.

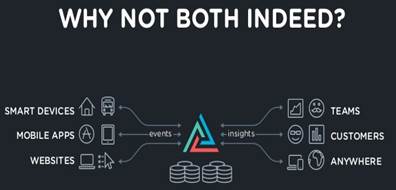

Data collection in the automotive, oil & gas, Pharmaceutical, packaging … in short all process industries plays a vital role. It helps personnel of all departments know where they stand, what is their target, what did they actually achieve! What if machine level controllers like a PLC (Programmable Logic Controller) or a PAC (Programmable Automation Controller) has built in data collection and storage feature? What if the same controllers can send that data to a cloud. IIoT is emerging. Implementing IIoT right in to a PLC or PAC which sends out data will give a competitive edge as data is right on the finger tips and strategic decisions can be made instantly.

Collective effort

Put together a Team and get all levels involved in the process of what data is needed. There can be things we might have overlooked that others familiar with the process will see. Others in the Group have to on board and getting their input will help. Groups or Teams can be an effective tool in this process.

Strategic Goals

Set Goals on how collecting the Data is going to improve the process or increase production. This will help with buy-in and drive the start of using the data collected